It did not take me long to learn that servo motor that I purchased, SG90, was not able to mount directly to either of the chassis platforms. A mount was required to hold the motor with the mount being screwed onto the platform. This lead to a problem. I could not find any online that were reasonably priced and did not take 2 to 4 months for shipping. It was surprising to see that there was very little on the market for mounting this servo motor which I thought was a common servo. It appears that most kits that use this servo come with a rectangular hole for the motor to fit in. Not what I have available.

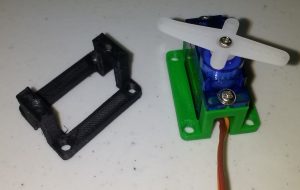

Searching online, I did find a few places with design files for 3D printing mounts for this servo motor. The one was a single piece unit. The another one consisted of two pieces, with each piece attaching to both ends of the motor. The one I chose was the single piece unit. Its design can be found at SG90 Servo Mount .

Now all I had to do is figure out how to print it since I do not own a 3D printer. Turns out there are services available that will print objects and ship them to you. Even Staples has a online 3D Printing Service. Luckily, a friend of mine, Doug Baxter, offered to print the mount for me. I am grateful for his help. He printed two mounts for me.

The mounts are a tight fit, which is good. The one thing that I did not expect was how tough the “ink” would be. It took more muscle power to screw in the two small screws that hold the motor in the mount. The next step is to go to a hardware store and get the right size nuts and bolts for attaching the mount to the chassis platform. Now that I have a mount in hand, determining the right size bolts will be simple.